In recent times, many of our clients in the oil and gas industry, including those in extraction and refining, have faced increasing demands for digital transformation in their operations and management. They aim to build Digital Twin models to enhance performance and management. However, we have observed that these initiatives often focus on the “how” of implementation, without sufficiently addressing the more critical question: “Why is digital transformation necessary?”

Challenges Faced Without 3D Technology in the Oil and Gas Industry

- Lack of Visual Management Tools: Refineries and oil rigs feature complex systems of pipes and equipment, making management and operations challenging without a 3D visual management model. Many facilities still rely on outdated 2D drawings or non-representative 3D models, leading to difficulties in real-time management and updating information during changes.

- Fragmented Management Systems: Managing in the oil and gas sector often requires combining and retrieving data from multiple systems. This fragmentation can waste time and create inefficiencies, as inconsistent data and the need to update and transfer information between systems can lead to errors and lack of synchronization.

- Complex Operational Monitoring: Operating and maintaining equipment typically involves interacting with various monitoring systems or even performing several manual tasks. This complexity results in inefficiency and increases the risk of errors in safety management and maintenance processes.

3D Solutions for the Oil and Gas Sector

To address these challenges, developed nations have advocated the implementation of Digital Twin models in the oil and gas industry, with 3D laser scanning technology playing a crucial role. Here are the key benefits of using 3D laser scanning in the oil and gas sector:

- Performance Optimization: Digital Twins enable monitoring and simulation of real-world operations in oil and gas facilities, helping to detect and optimize performance from supply management to production process adjustments.

- Predictive Maintenance: Digital Twins can predict potential failures and incidents before they occur, enabling proactive measures in operations management.

- Project and Design Optimization: In new construction and development phases, Digital Twins help design and optimize facilities, from selecting the optimal location to refining production processes.

- Cost and Resource Savings: Digital Twins help reduce operating and maintenance costs by optimizing resource use and predicting failures.

- Risk and Safety Management: Digital Twins can simulate hazardous scenarios and provide safety information, helping to manage risks and ensure safety for both personnel and the environment.

- Data Management and Estimation: Digital Twins allow the collection and management of data from multiple sources, improving estimation, planning, and asset management processes.

- Regulatory Compliance: Digital Twins help monitor and report on compliance with regulations and standards in the oil and gas industry.

The Role of 3D Technology in Building Digital Twins for the Oil and Gas Sector

3D laser scanning technology plays a vital role in building Digital Twin models for the oil and gas sector, offering the following benefits:

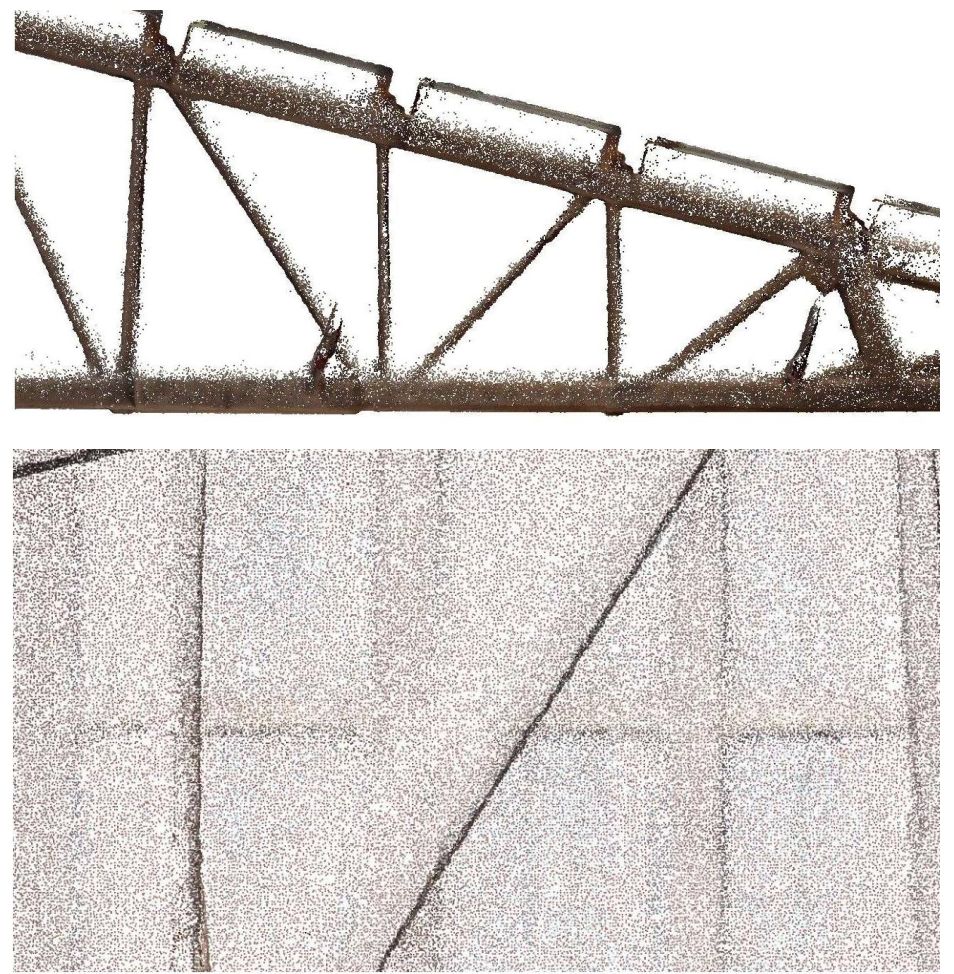

- Accurate Data Collection: 3D laser scanning uses lasers to collect highly accurate data about plant structures, equipment, pipelines, and other details, helping to create precise digital replicas of facilities and their systems.

- Dynamic 3D Modeling: 3D laser scanning can create dynamic (4D) models by repeating scans at fixed intervals, allowing for real-time tracking of changes and fluctuations within a facility.

- Investigation and Analysis: Data from 3D laser scanning is used to investigate and analyze issues such as performance and safety, improving operational management and leading to informed decision-making.

- Optimized Design and Construction: 3D laser scanning provides valuable insights for new construction or upgrades, ensuring accurate design and minimizing errors.

- Maintenance and Repairs: This technology aids in assessing the condition of equipment and infrastructure, predicting and detecting issues early, optimizing maintenance schedules, and enhancing safety.

Experience and Considerations in Implementation

- 3D Laser Surveying: Conducting surveys using 3D laser scanning technology is a critical step that must be carried out with high precision. This ensures that the collected data is reliable and can be utilized in future applications.

- Data Processing and Visualization: Survey data is typically vast and complex. Processing and visualizing this data requires professional software and interactive capabilities, facilitating easier information sharing and management.

- The Life of a Digital Twin: A Digital Twin is only effective if it is continuously updated with management information and sensor data from the field. To achieve this, it is essential to understand IoT devices and how to interact with them to capture and display data on a 3D model.

- Choosing an Experienced Partner: Implementing a Digital Twin is a complex task that requires expertise. Selecting a partner with experience and credibility in this field is crucial for the project’s success.

VMT Solutions brings expertise in accurate data surveying and processing, developing 3D viewer solutions, and integrating management information into 3D models. We are ready to help turn your ideas into reality and add value to the oil and gas industry. Share your ideas with us to start a collaboration.

Frequently Asked Questions (FAQs)

When should we consider and implement digital transformation or a Digital Twin?

Digital transformation has become a critical requirement for many industries today. The extent of implementation depends on the specific needs of your facility. You should consider digital transformation and the use of a Digital Twin when you need to:

- Optimize Performance: If you aim to enhance the performance of a system or process, digital transformation and a Digital Twin can help you monitor, analyze, and improve operations more efficiently.

- Manage Risk: When you need to manage risk and predict potential failures, a Digital Twin can simulate hazardous scenarios and provide information to make safer decisions.

- Asset Management: For effective asset tracking and management, a Digital Twin gives you a comprehensive overview of the status and condition of your assets.

- Design and Product Development: In manufacturing, a Digital Twin can be used to design and develop new products, from simulating production processes to testing and validation.

- Infrastructure Management and Operation: In sectors like energy, transportation, and urban infrastructure, a Digital Twin can help manage and operate systems efficiently.

- Regulatory Compliance: When you need to comply with strict regulations and standards, a Digital Twin allows for effective monitoring and reporting on compliance.

- Project Management: For construction and project management, a Digital Twin can be used to monitor progress and manage resources.

- Enhance Customer Experience: In industries like retail and services, a Digital Twin can improve customer experience by creating a digital replica of a product or service.

Digital transformation and the use of Digital Twins can be applied across various contexts and industries to improve management, optimize operations, and ensure compliance with industry standards and requirements.

Does implementing a Digital Twin require a large budget?

If budget constraints are a concern when initiating a project, our experience allows us to help you break down the implementation into manageable phases. This phased approach enables management to clearly see the benefits and value generated, allowing for reinvestment into subsequent stages.

What expertise should your partner have to implement a Digital Twin?

Implementing a Digital Twin involves several key phases:

-

Reality Capture and Digitization:

- If you are using laser scanning, it’s crucial to have accurate data, especially since you’ll rely on it for future renovations, layout adjustments, or repairs. Inaccurate data due to lack of expertise can lead to unreliable outcomes. Ensure your provider has strong expertise in field surveying, as this is a critical requirement.

-

3D Model Visualization:

- Typically, providers may simply upload data to a platform and deliver an online viewer to the client. However, you should verify this approach, as it can lead to complete dependence on a third-party solution, which may involve ongoing maintenance costs, limited editing capabilities, and data security concerns. If your partner can develop an independent viewer, it’s a significant advantage that addresses all these issues.

-

Data Integration and Sensor Information Display:

- This phase is particularly challenging, as it involves not only software programming but also hardware interaction. Most existing facilities have devices in use, and integrating these devices into the Digital Twin can be difficult. Check the case studies your partner has implemented and their solutions to ensure they can meet these demands.

Implementing a Digital Twin requires a partner with multidisciplinary expertise, including laser scanning surveys, 3D digitization, optimized 3D visualization (detailed yet lightweight for web display), 3D viewer programming, and hardware integration. Ensure your partner has the capability and expertise across these diverse areas.

Recent Posts

Tag Cloud

PRESSE

We take pride in having

satisfied customers.

„Your plans are perfect; I’ve never seen anything like this before. These are drawings of the highest quality, I must say. I want to express my sincere thanks once again for your work.“

VMT modeled a large industrial building in 3D for our research project. We provided DWG plans to VMT, and they delivered a highly detailed model, including the building envelope, interior walls, openings, and stairs. We had previously contracted a German company for the same object, but unfortunately, it didn’t work out. I was relieved and pleased that VMT handled it so reliably. Thank you for the excellent work and the truly fair price!

Very reliable company, courteous staff, and top-quality work. Our plans were created quickly and accurately. Thank you for that. Highly recommended.

Excellent advice and high 3D modeling quality at a great price-performance ratio… What more could you want? I can highly recommend them…