The 3D laser scanning (3D Laser Scanning) technology is becoming an indispensable tool in construction, architecture, heritage conservation, and industry. With the ability to capture millions of precise data points in a short time, 3D scanning brings outstanding benefits such as reduced survey time, higher accuracy, design support, and construction verification.

However, if not executed with the right techniques and workflow, the 3D scanning process can introduce serious errors that affect the entire project outcome. In this article, VMT SOLUTIONS analyzes common mistakes in 3D scanning—their causes, consequences, and prevention measures—to help you maximize the effectiveness of this modern technology.

Table of Contents

Overview of the 3D Scanning Workflow

Before exploring common errors, it’s important to understand the main steps of a complete 3D scanning workflow:

- Site reconnaissance: Assess scanner placement, lighting conditions, obstacles, etc.

- Setup and calibration: Adjust height and orientation to ensure optimal field of view.

- Field scanning: Capture data from multiple scan stations.

- Registration: Merge the scan datasets into a single coherent set.

- Point‑cloud processing: Denoise, classify/layer, and build 3D models or as‑built drawings.

- Quality check and data delivery: Ensure outputs meet technical and software requirements.

Errors can occur at any stage of this workflow if control is lacking.

Common Errors in 3D Scanning

1. Errors in Site Preparation

❌ No pre‑scan site survey

Skipping a preliminary site survey often leads to placing the scanner where views are blocked, missing critical areas, or overlooking interference factors such as reflective lighting, glass surfaces, water, etc.

❌ Lack of contingency planning

In complex environments (active construction, underground spaces…), failing to prepare spare batteries, memory cards, tripods, and supporting tools can interrupt the session or compromise the entire scan.

2. Errors in Scanner Setup and Calibration

❌ Incorrect placement and non‑optimal scan angles

One of the most common mistakes is insufficient spatial coverage from scan stations, or positioning too close to objects, causing data loss. Poor scanner angles also introduce geometric distortion.

❌ No device calibration

Laser scanners must be checked regularly for accuracy. Using equipment that is out of calibration or with uneven sensors will severely degrade the captured data.

3. Errors During Scanning

❌ Insufficient coverage, missing data

If operators don’t verify overlap between scan stations, missing data “holes” can occur in occluded areas such as ceiling corners, columns, or behind obstacles.

❌ Motion‑induced noise during scanning

People moving, vehicles, changing light, etc., can create erroneous points known as noise points. Without post‑processing, this noise complicates modeling.

❌ Incorrect technical settings

Parameters such as resolution, point spacing, scan frequency must match the project type; otherwise you’ll have redundant or insufficient data and slower processing.

4. Errors in Data Registration

❌ Using too few control points

Registration merges point clouds from multiple stations. If too few targets are set or not enough common features are recognized, datasets will misalign or fail to merge.

❌ Not checking misalignment between scans

Skipping post‑registration error checks leads to axis shifts, tilting, or scaling issues, causing errors across the entire model.

5. Errors in Point‑Cloud Processing

❌ No denoising or data optimization

Raw point clouds are heavy (hundreds of millions of points). Without denoising, classification, and reasonable decimation, modeling or importing into BIM software becomes difficult.

❌ Mistakes when modeling from the point cloud

Some auto‑modeling tools struggle with curved, slanted, or non‑standard structures. Over‑reliance on AI without verification can produce inaccurate drawings.

6. Errors in QA and Handover

❌ No model validation against standards

Final data must be checked for deviation, file formats, coordinate systems, metadata, etc. Skipping validation makes integration with design or BIM software difficult.

❌ Deliverables not matching client requirements

Each client may require different formats: .e57, .rcs, .ifc, .rvt, .dwg… Delivering missing or incorrect formats forces rework and affects project schedules.

Consequences of Errors in 3D Scanning

Below are serious consequences if errors aren’t detected and corrected early:

- Design inaccuracies: Incorrect BIM models or as‑built drawings will trigger downstream errors in design, fabrication, and construction.

- Rework costs: Rescanning or remodelling consumes significant time and budget.

- Schedule delays: Wrong deliverables disrupt the entire timeline of designers or contractors.

- Damaged professional reputation: Technical errors reduce client trust—especially on large projects.

How to Minimize and Prevent Errors in 3D Scanning

To ensure the quality and reliability of 3D scan data, follow these principles:

✅ Thorough preparation before scanning

- Survey the site in detail and plan scan stations.

- Prepare spare equipment, batteries, memory cards, and incident‑response scenarios.

✅ Inspect and calibrate equipment

- Check lasers, sensors, and controllers before each project.

- Run trial scans to assess quality.

✅ Tight process management

- Follow the 6‑step standard workflow (as outlined in Section II).

- Define naming conventions, coordinates, and metadata from the start.

✅ Cross‑check and acceptance

- Use specialized software to validate the model.

- Perform cross‑handover between engineering and QA to control quality.

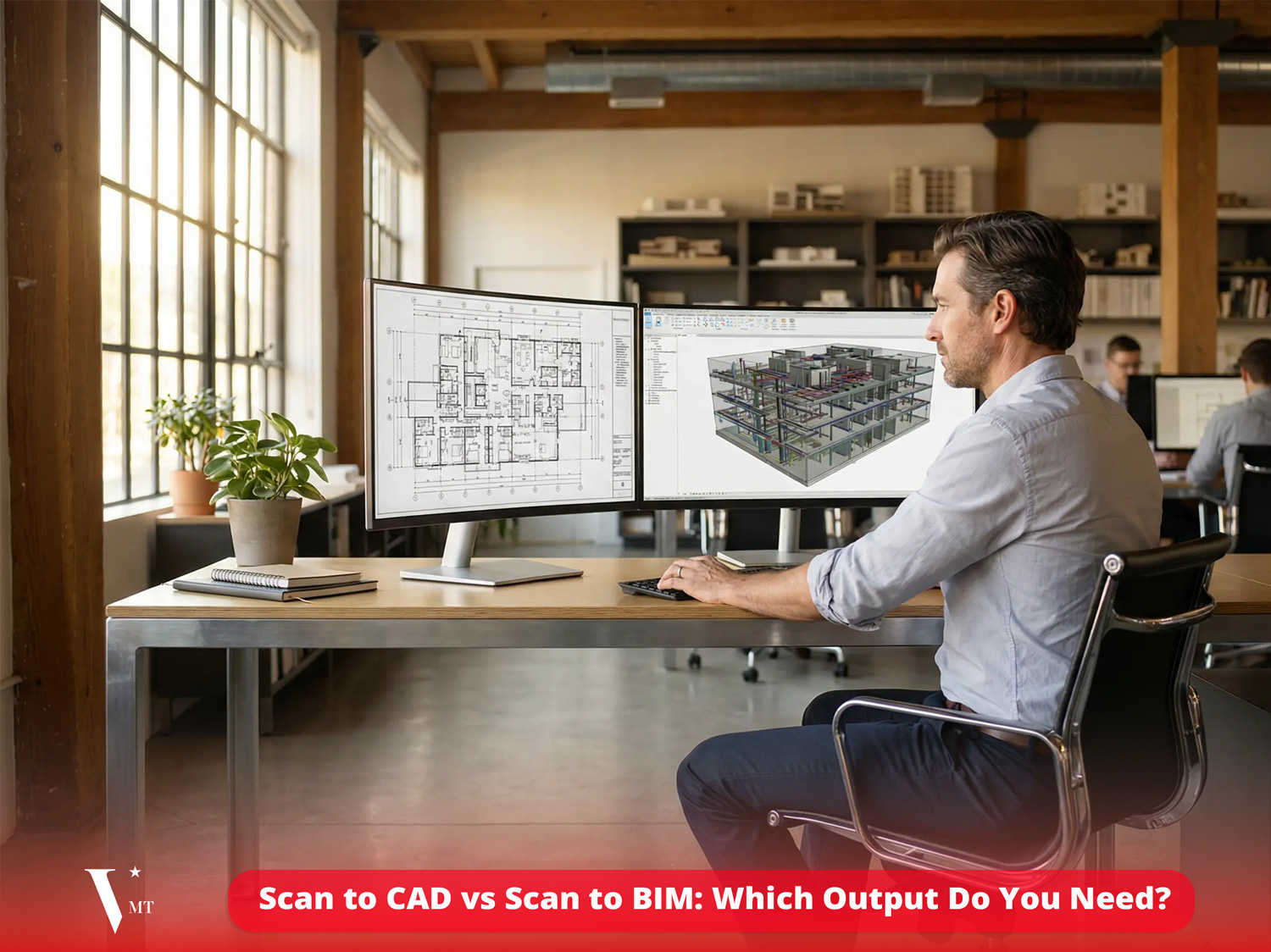

Accurate & Professional 3D Scanning Services from VMT Solutions

At VMT Solutions, we understand that accuracy to the millimeter in 3D scan data is critical to a project’s success. With a well‑trained technical team, modern equipment, and rigorous quality control, we are committed to eliminating common 3D‑scanning errors from initial survey to final delivery.

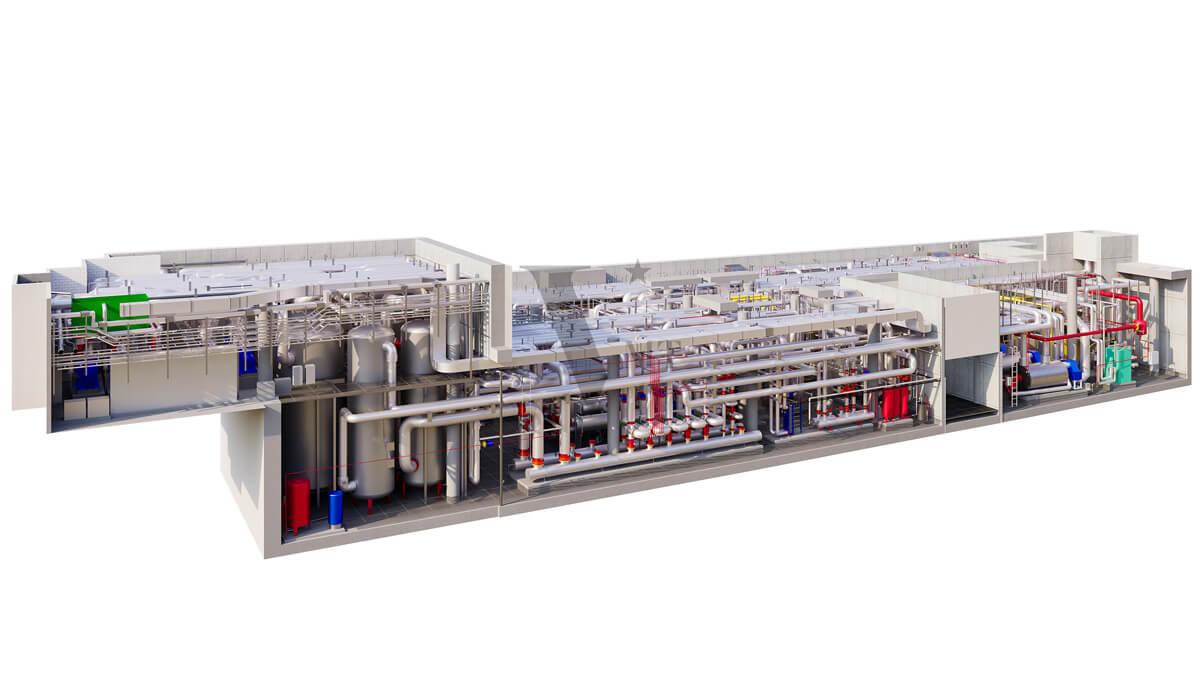

We don’t just provide point‑cloud data—we also deliver complete services: BIM modeling, as‑built drawings, and integration with Revit, Archicad, AutoCAD, and more, suitable for all project types—from residential buildings and industrial plants to infrastructure and heritage assets.

Contact VMT Solutions for advice and to receive the most suitable, accurate, and cost‑effective 3D scanning solution for your project.

About the Author:

Nguyen Huynh (Rainer)

As the Co-Founder and Chief Executive Officer of VMT Solutions, SSIFT Vietnam, BlackSwiss Vietnam, and Victoria Measuring Solutions PTY LTD (Australia), I completed my Master’s program in Technical and Vocational Education and Training (TVET) in Germany in 2007.

With over a decade of experience in point cloud processing and BIM services, I am passionate about tackling complex challenges and developing innovative workflows to enhance accuracy and detail in point cloud-to-BIM conversion.

At VMT Solutions, we are committed to delivering high-quality services that provide exceptional value, especially for surveying companies. We focus on building mutually beneficial partnerships, ensuring that our clients receive customized solutions tailored to their specific needs. Every day, I strive to push the boundaries of the industry, continuously improving our methods and exploring new ways to optimize the services we provide.

Recent Posts

Tag Cloud

We are proud to have

satisfied customers.

„Your plans are perfect; I’ve never seen anything like this before. These are drawings of the highest quality, I must say. I want to express my sincere thanks once again for your work.“

VMT modeled a large industrial building in 3D for our research project. We provided DWG plans to VMT, and they delivered a highly detailed model, including the building envelope, interior walls, openings, and stairs. We had previously contracted a German company for the same object, but unfortunately, it didn’t work out. I was relieved and pleased that VMT handled it so reliably. Thank you for the excellent work and the truly fair price!

Very reliable company, courteous staff, and top-quality work. Our plans were created quickly and accurately. Thank you for that. Highly recommended.

Excellent advice and high 3D modeling quality at a great price-performance ratio… What more could you want? I can highly recommend them…