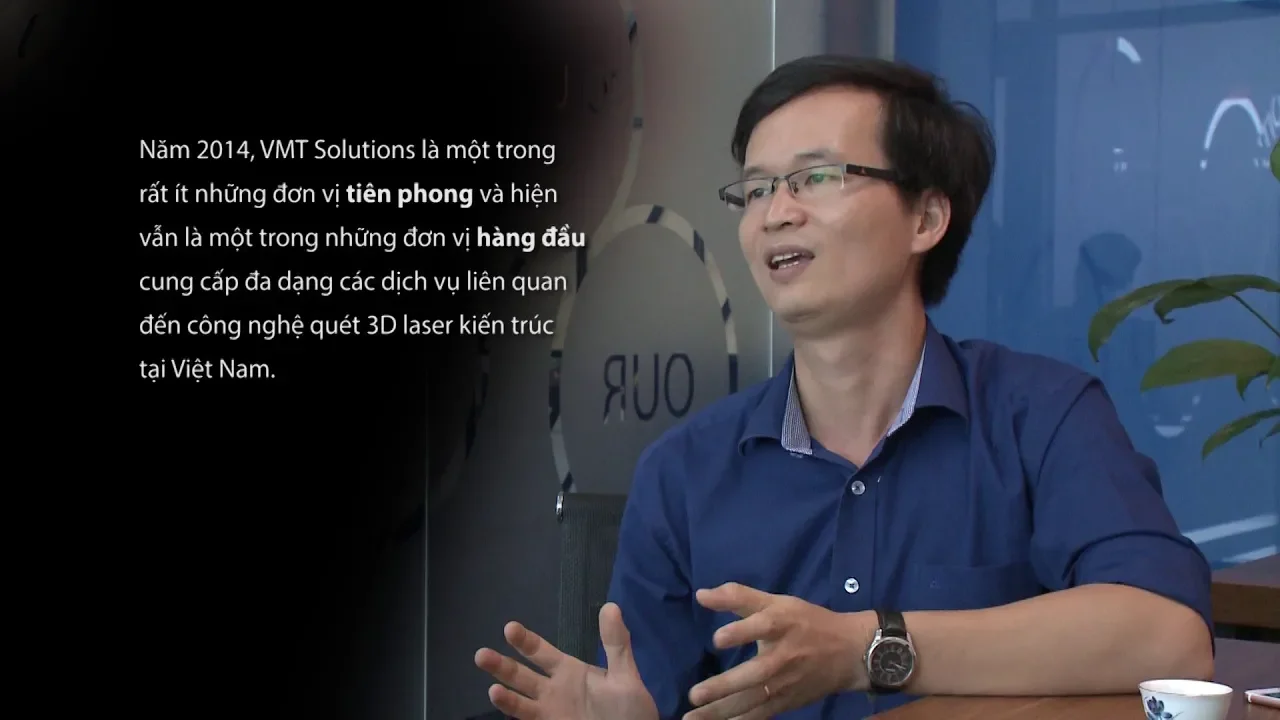

Though we started applying laser scanning in Vietnam as early as 2009, only a few clients in Vietnam saw the advantages of this technology. Recently, however, more clients have expressed interest in leveraging this new technology to optimize their processes. We’ll start sharing a use case that we’re applying to help an interior design company in Vietnam and consider their future applications.

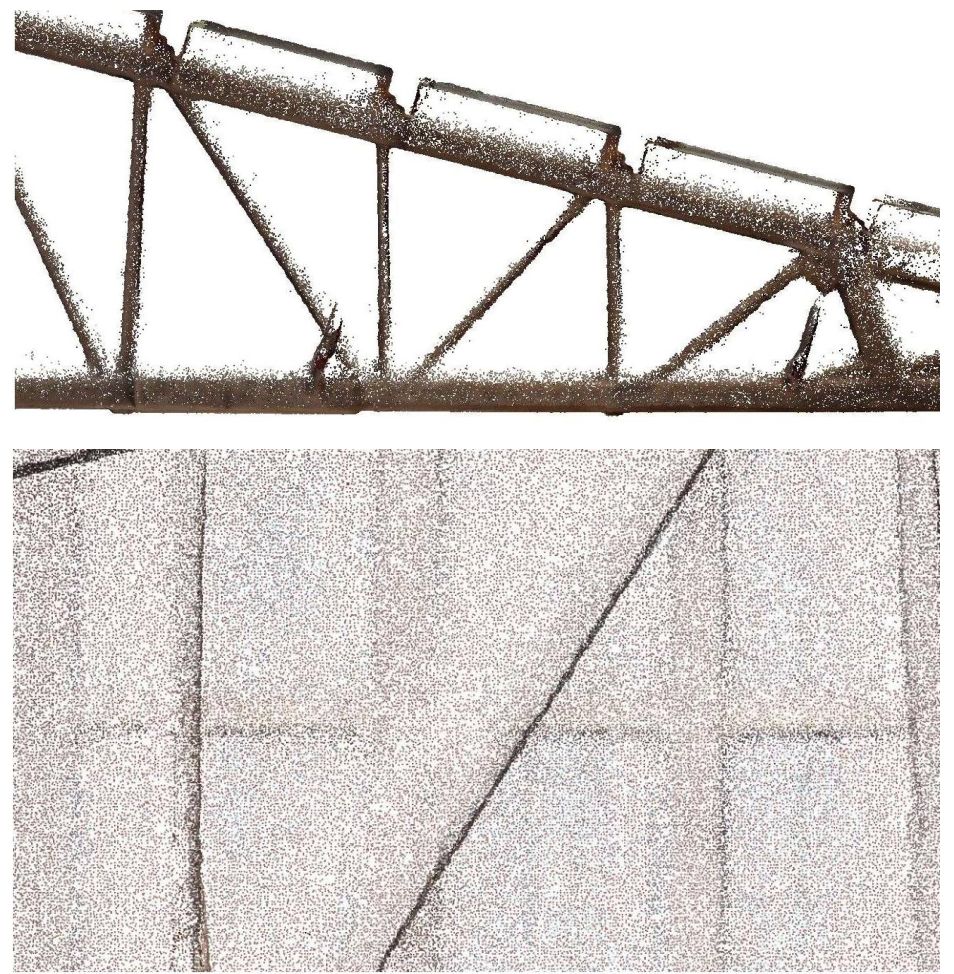

In the construction industry, designing and constructing buildings is a very complex process that requires high accuracy. And installing railings that bend with the curved staircases is one of the most significant challenges for interior designers.

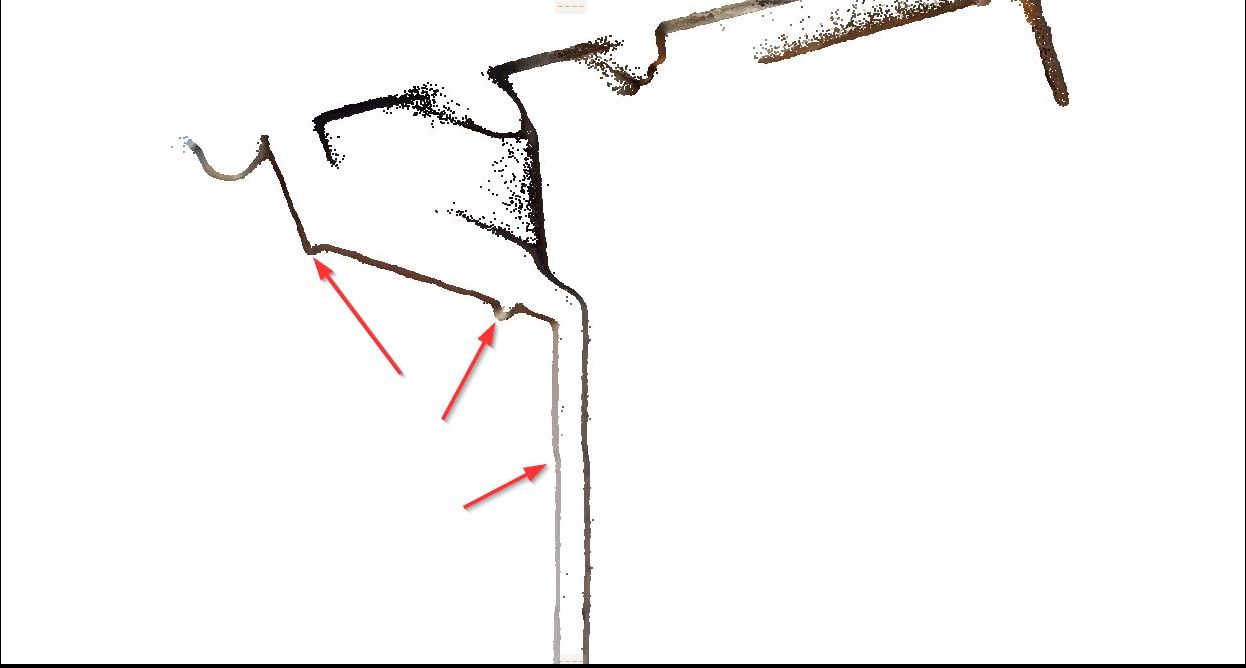

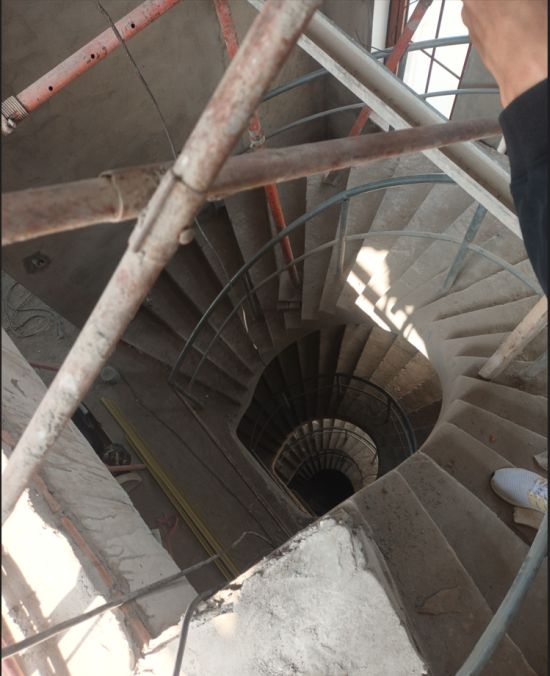

In a four-story villa project, after completing the raw construction, the interior designer wanted to install railings that bend along the curved staircase using stainless steel combined with glass. However, due to the twisted railing design, CNC manufacturing and bending are extremely complicated.

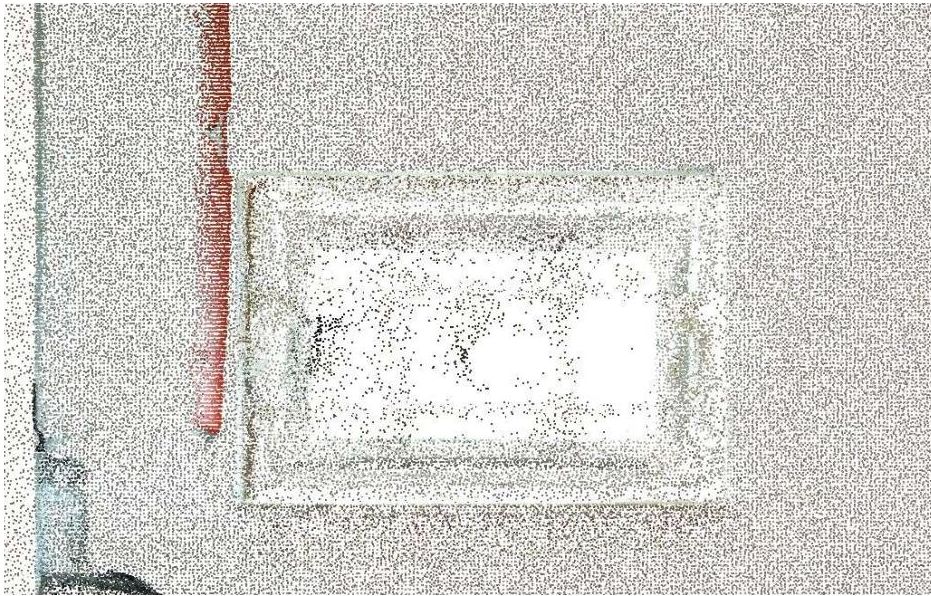

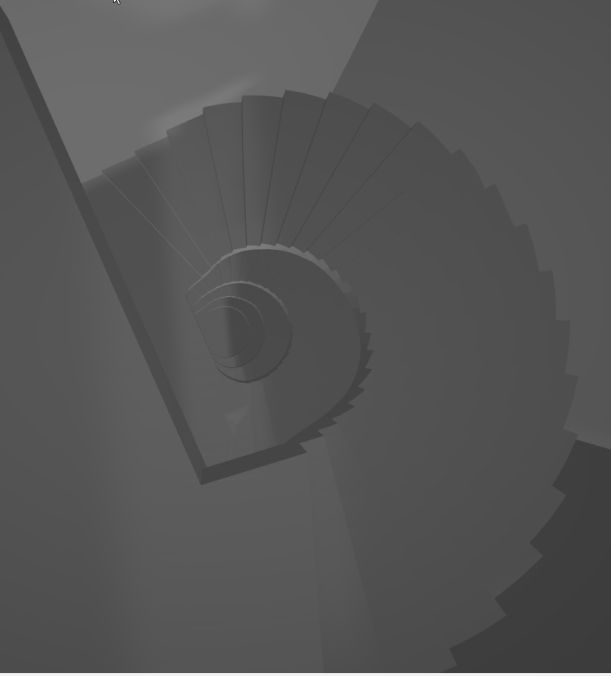

To ensure the accuracy of the project, they needed an accurate assessment of the current state of the staircase to compare with their design. The result of comparing the current state of the staircase with its design showed significant differences that needed to be adjusted.

If traditional measuring methods were used, it would take a lot of time and cost. Moreover, when installing the railings into the construction, there could be a mismatch that would waste time, increase costs, and increase the risk of delaying the project.

In this case, a good solution was to use 3D laser technology to measure the current state of the staircase. Although the initial cost of using this method was more expensive, the measurement results were highly accurate, helping to minimize the risk when installing railings and ensuring the quality of the construction.

The success of this project has changed the mindset of our client regarding applying technology to interior design. It helped him understand more about the benefits and potential of laser scanning in enhancing accuracy and efficiency in design as well as reducing risks and costs in the construction process.

With the experience gained from this project, the interior design company has realized the value of technology in interior design and construction and continues to apply high-tech to future projects. Using 3D laser technology has helped their company increase its professionalism and improve the quality of its products, thereby building trust and attracting new customers.

Therefore, applying high-tech solutions such as 3D laser technology in interior design and construction is essential to meet the increasing demand for accuracy, efficiency, and quality in today’s construction industry.

Recent Posts

Tag Cloud

PRESSE

We take pride in having

satisfied customers.

„Your plans are perfect; I’ve never seen anything like this before. These are drawings of the highest quality, I must say. I want to express my sincere thanks once again for your work.“

VMT modeled a large industrial building in 3D for our research project. We provided DWG plans to VMT, and they delivered a highly detailed model, including the building envelope, interior walls, openings, and stairs. We had previously contracted a German company for the same object, but unfortunately, it didn’t work out. I was relieved and pleased that VMT handled it so reliably. Thank you for the excellent work and the truly fair price!

Very reliable company, courteous staff, and top-quality work. Our plans were created quickly and accurately. Thank you for that. Highly recommended.

Excellent advice and high 3D modeling quality at a great price-performance ratio… What more could you want? I can highly recommend them…