So, how can costly errors be eliminated and complex processes optimized?

The answer lies in a breakthrough technology: 3D Laser Scanning.

Table of Contents

What Is 3D Laser Scanning and How Does It Work?

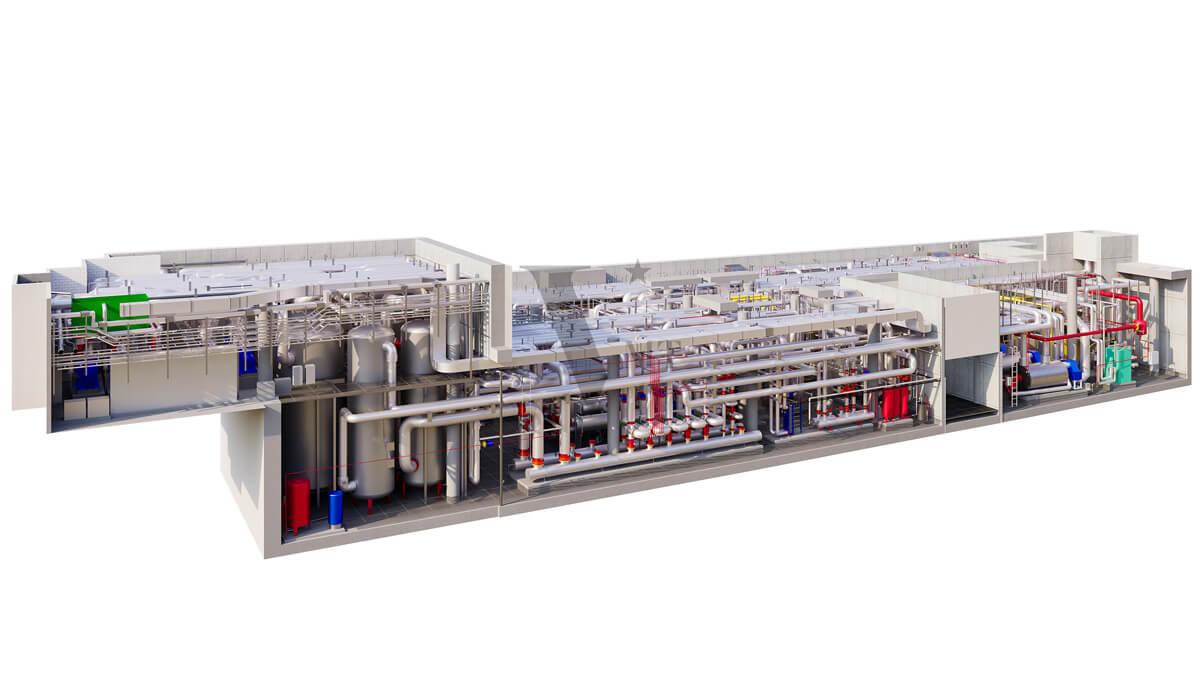

3D laser scanning is revolutionizing the way we approach construction projects, especially in the MEP field. This technology uses laser (LiDAR) beams to measure millions of points in real space with incredible speed and accuracy.

- Ultra-fast data collection: A single scanner can record millions of data points (called a point cloud) within minutes, creating a precise 3D digital replica of the site.

- Exceptional accuracy: Measurement deviations are within just a few millimeters, providing engineers with highly reliable data.

- A foundation for BIM: The point cloud data is processed and integrated into a Building Information Model (BIM), forming a visual and accurate database for planning, coordination, and construction.

The Strategic Benefits of 3D Laser Scanning for MEP Contractors

In leading construction markets such as the United States, Germany, and Japan, 3D laser scanning has become an essential standard. For MEP contractors, this technology delivers the following strategic advantages:

1. Early Clash Detection

By combining real-world point cloud data with the BIM design model, contractors can detect and resolve conflicts between MEP systems and structural or architectural elements before construction begins. This completely eliminates costly change orders and on-site delays.

2. Optimized Design and Prefabrication

With as-built drawings accurate to the millimeter, components such as ducts, pipes, and cable trays can be prefabricated in workshops. When brought to the site, they fit perfectly in place, significantly reducing time, labor costs, and construction risks.

3. Real-Time Quality Assurance (QA/QC)

Throughout the construction process, periodic scanning data can be compared with the design model. Any deviations from the drawings are detected immediately, allowing engineers to make timely adjustments and ensure consistent quality control.

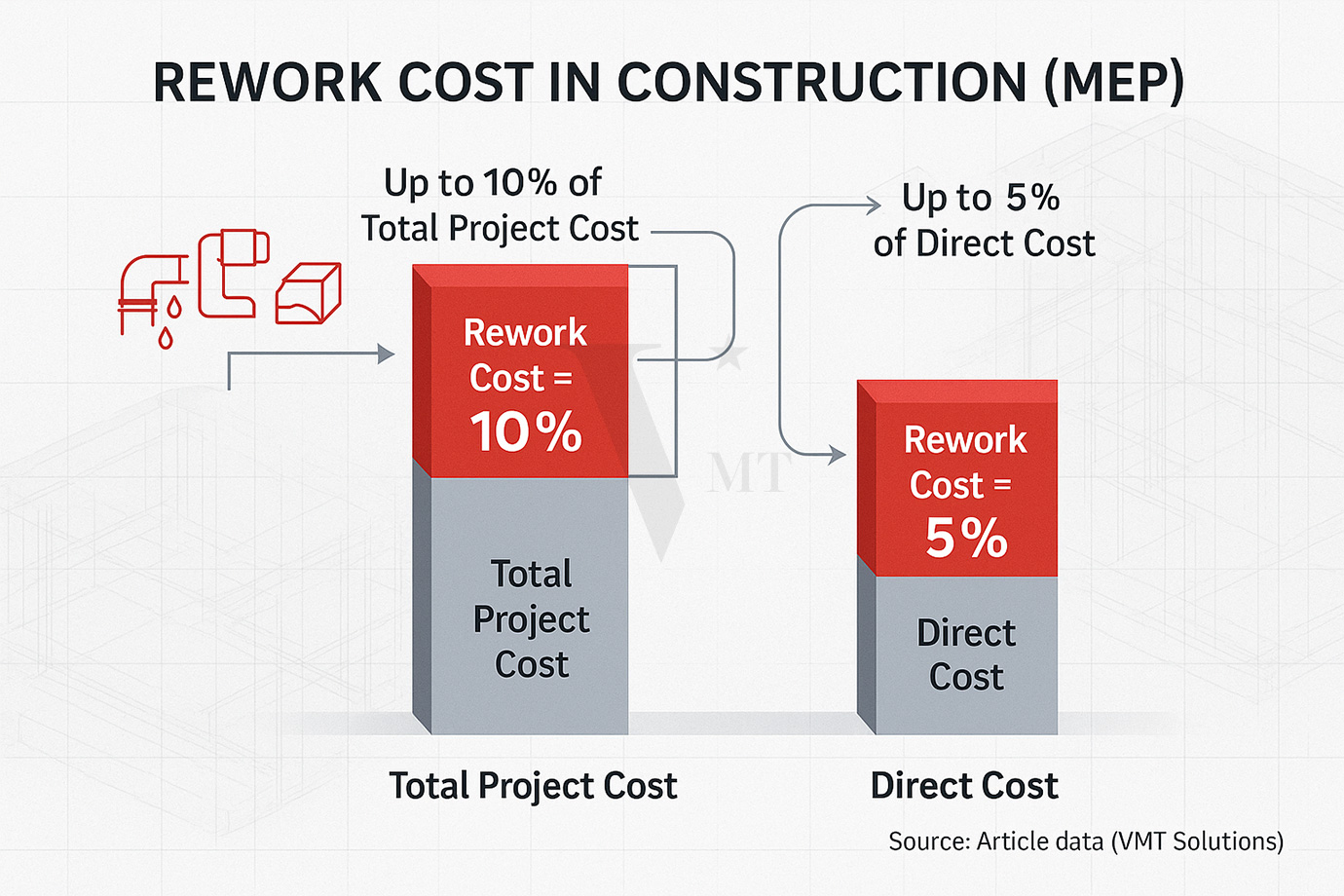

4. Minimized Rework and Losses

Errors during construction often result from clashes between systems caused by discrepancies between the actual site and the design drawings. If the MEP team relies solely on design drawings and skips laser scanning, the risk of installation clashes is extremely high.

The result: costly rework, delays, and loss of professionalism.

Did you know? Rework costs can account for up to 5% of direct expenses and 10% of the total project budget. Detecting a misaligned pipe bend just a few centimeters off during pre-construction scanning takes only minutes to fix. But if construction proceeds without verification, the losses could reach hundreds of millions of VND due to demolition, redesign, or reinstallation.

The following table provides an illustrative comparison of rework cost rates (as a percentage of budget) across regions, before and after using laser scanning:

| Region / Case | Without Laser Scanning (Estimated) | With Laser Scanning (Estimated) |

|---|---|---|

| United States (Typical) | ~18% of project budget | ~10% (↓ ~44%) |

| Europe (Typical) | ~15% | ~8% (↓ ~47%) |

| Australia (Typical) | ~20% | ~12% (↓ ~40%) |

| Asia (Typical) | ~17% | ~9% (↓ ~47%) |

3D laser scanning acts as the “smart eyes” of your project — identifying issues early, preventing risks, and minimizing rework costs from the very first stage.

Real-World Results from Sample Projects

Below are some representative examples showing cost and time improvements when applying laser scanning in MEP projects across countries:

| Country (Company) | Project / Application | Key Savings | Reference Source |

|---|---|---|---|

| USA (CHI Eng.) | EPC NLG (Liquefied Gas) Plant – As-built survey | 10–20% cost reduction and 50% time savings in data collection by scanning the entire site in a single session. | FARO Case Study |

| USA (Warner Mech.) | MEP installation for a 250,000 ft² arena | Measurement time reduced from 2–3 days to just 1 day (↓ ~50–66%) using laser scanning instead of manual measuring. | Trimble Field Tech |

| USA (EC Electric) | MEP layout installation | 90% labor savings in layout preparation using 3D scanners (TX6) and modeling. | Trimble Field Tech |

| Australia (Gandy & Roberts) | $74M school project (5 new buildings) | Detected pipe and component misalignments before concrete pouring, preventing weeks of costly rework later. | NavVis Blog |

The table above compares projects using laser scanning vs. traditional methods (without scanning).

For instance, CHI Engineering (USA) reduced total costs by 10–20% and cut survey time by half. Warner Mechanical shortened MEP data collection from several days to one.

In Australia, Gandy & Roberts detected design errors early in a school project, saving a significant amount of rework costs.

NavVis reports show that 10–20% of project budgets are often lost to rework under traditional methods, while accurate as-built data from laser scanning dramatically reduces this figure.

VMT Solutions: Leading 3D Laser Scanning in Vietnam

In Vietnam, VMT Solutions is one of the leading providers of professional and efficient 3D laser scanning services. We don’t just provide data — we deliver complete solutions.

- Accurate surveys: Delivering point cloud data with the highest precision.

- In-depth analysis: Providing consulting, analysis, and comparison between scanned data and design models to identify deviations and potential clashes.

- Proven efficiency: Projects in collaboration with VMT Solutions have significantly reduced rework time on site, optimized resources, and enhanced contractor credibility.

Advice for Contractors: Partner with Experts to Maximize Efficiency

To fully harness the power of this technology, choosing the right partner is crucial.

- Avoid inaccurate data: Inexperienced survey firms can provide flawed data, negating the benefits of the technology investment.

- Actionable data matters: A raw point cloud file is not enough. The data must be processed, analyzed, and formatted so on-site teams can immediately understand and use it.

- Focus on your expertise: Partnering with experts like VMT Solutions saves you time, prevents costly mistakes, and allows you to focus on your core strength — construction execution.

Conclusion

As the construction industry demands greater speed, quality, and cost efficiency, 3D laser scanning is no longer a “nice-to-have” option — it has become an essential tool.

It helps MEP contractors minimize risks, improve quality, and strengthen their competitive position in the market.

Don’t let preventable errors impact your project’s timeline or profitability. Contact VMT Solutions today to get expert advice on the most suitable 3D laser scanning solution for your project!

About the Author:

Nguyen Huynh (Rainer)

As the Co-Founder and Chief Executive Officer of VMT Solutions, SSIFT Vietnam, BlackSwiss Vietnam, and Victoria Measuring Solutions PTY LTD (Australia), I completed my Master’s program in Technical and Vocational Education and Training (TVET) in Germany in 2007.

With over a decade of experience in point cloud processing and BIM services, I am passionate about tackling complex challenges and developing innovative workflows to enhance accuracy and detail in point cloud-to-BIM conversion.

At VMT Solutions, we are committed to delivering high-quality services that provide exceptional value, especially for surveying companies. We focus on building mutually beneficial partnerships, ensuring that our clients receive customized solutions tailored to their specific needs. Every day, I strive to push the boundaries of the industry, continuously improving our methods and exploring new ways to optimize the services we provide.

Recent Posts

Tag Cloud

We are proud to have

satisfied customers.

„Your plans are perfect; I’ve never seen anything like this before. These are drawings of the highest quality, I must say. I want to express my sincere thanks once again for your work.“

VMT modeled a large industrial building in 3D for our research project. We provided DWG plans to VMT, and they delivered a highly detailed model, including the building envelope, interior walls, openings, and stairs. We had previously contracted a German company for the same object, but unfortunately, it didn’t work out. I was relieved and pleased that VMT handled it so reliably. Thank you for the excellent work and the truly fair price!

Very reliable company, courteous staff, and top-quality work. Our plans were created quickly and accurately. Thank you for that. Highly recommended.

Excellent advice and high 3D modeling quality at a great price-performance ratio… What more could you want? I can highly recommend them…