A customer who had experienced multiple failures while implementing Laser Scanning to BIM for their factory reached out to us, seeking assistance. They wanted us to share their story of the Laser Scanning to BIM deployment process as a reference for other companies to learn from

Table of Contents

Summarize the article

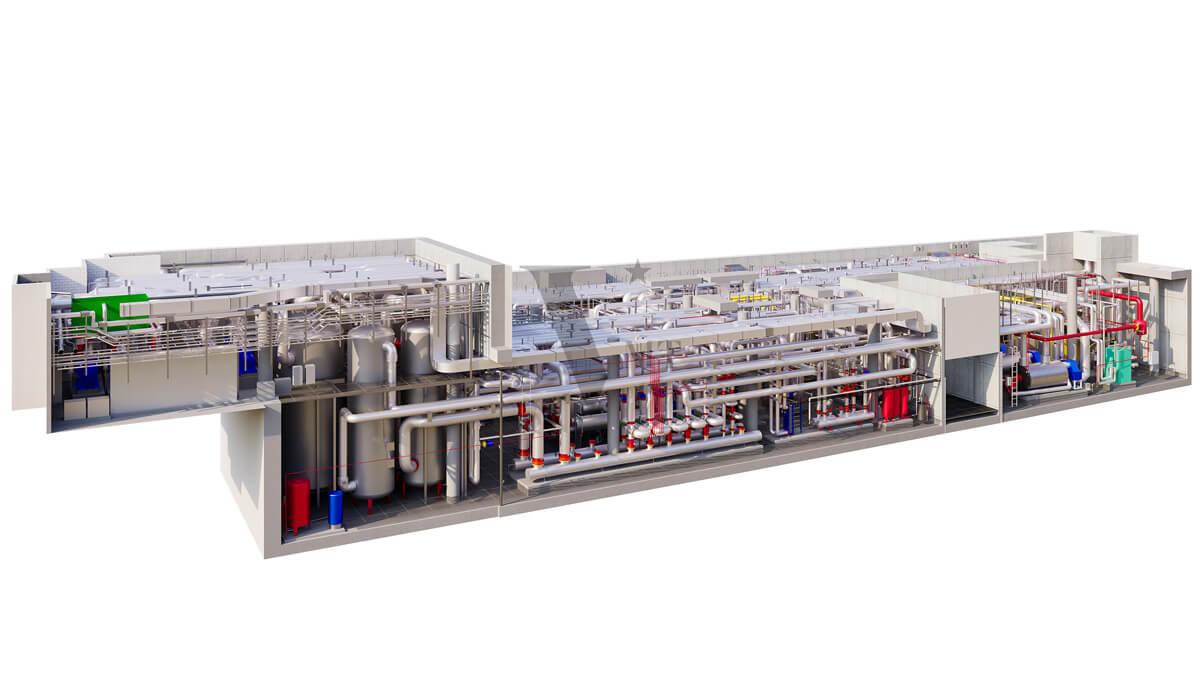

To achieve accurate 3D BIM modeling from the as-built 3D laser survey data, precision must be ensured throughout every stage of execution.

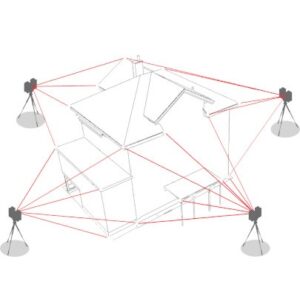

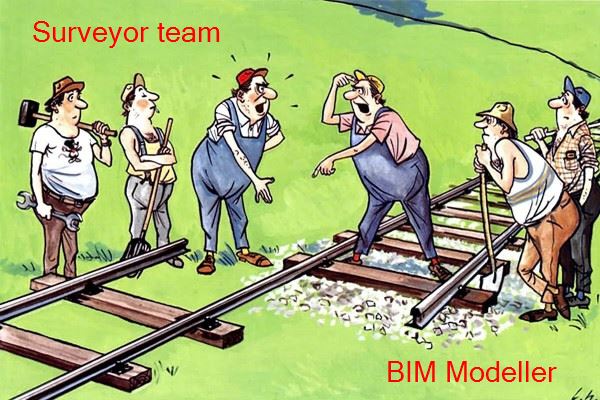

We can divide this process into two main stages: the 3D laser scanning survey and 3D modeling. Both stages require precise execution, and ideally, both teams involved should collaborate closely, understanding each other’s roles and expectations. Immediate communication should be established whenever discrepancies arise. Only through such collaboration can the final results guarantee accuracy.

Detailing the Failures of the Laser Scanning to BIM

“I’ve been tasked with finding a company to assist in the digital transformation process for creating a Digital Twin of our factory. It’s a significant and challenging task because I lack the knowledge and experience needed to assess the quality of potential providers, and there may be hidden risks involved.

After conducting research online, I’ve come to understand that the Laser Scanning to BIM process consists of two crucial steps: 1. Conducting a 3D laser scanning survey and 2. Processing the data into a 3D digital model.

- Step 1: Conducting a 3D Laser Scanning Survey

- Step 2: Point Cloud to BIM Modelling

Searching for a provider on the internet was a surprising experience, as there were numerous companies offering this service, each boasting their impressive experience. After reaching out and collecting multiple quotes, I realized that cost optimization could be achieved by splitting the process into two phases and assigning each to a different provider with the best quotes.

Everything proceeded smoothly, and the laser scanning data collection process did not disrupt the daily operations of the factory. I closely monitored the scanning process and was impressed with the equipment; I had high expectations that the final results would be highly accurate, pleasing our boss.

Moving on to the second step, the data was handed over to a BIM modeling company, and their website showcased various projects and extensive experience in processing point clouds into BIM models. After the implementation period, I received a complete 3D model. My initial impression was positive; the entire factory had been digitized into a 3D model, which would undoubtedly simplify equipment management and replacements in the future.

However, not everything went smoothly. When implementing the retrofit equipment layout, I encountered discrepancies with the actual setup, particularly instances where machinery was in close proximity to steel columns, with gaps of up to 10cm. My boss expressed disappointment and concern as we couldn’t find a quick solution. I decided to hire a surveying company to recheck the as-built drawings, and they discovered inaccuracies in many other critical locations. New issues began to arise when two subcontractors disputed responsibility in a meeting to avoid damage compensation.

Analyzing and comparing the drawings and point cloud data gradually revealed the error’s origins. The 3D laser scanning was conducted by an inexperienced surveying team who lacked expertise in land surveying. Although they had experience from several projects, their main focus was on visualization purposes, with little regard for the actual accuracy. Therefore, they relied on their experience, believing they could meet all project requirements. The point cloud data’s verification by a professional surveying team exposed many inaccuracies in crucial locations.

The 3D modeling team could recognize these errors but adopted an approach of taking average values and making on-the-spot adjustments in an attempt to reduce discrepancies. However, they did not communicate the discrepancies in the point cloud data, as they believed their task was solely to create a model based on the provided data.

Determining liability for compensation due to inaccuracies in the as-built model became challenging. Some argued that the surveying company should bear responsibility because of the inaccurate point cloud data. Others contended that the modeling team had detected discrepancies but failed to report them, diminishing their responsibility and professionalism.

The arguments may not have reached a resolution, but the urgency of the situation called for finding a company with hands-on experience to address the problem. Fortunately, I came across VMTS. Although adjusting the survey data was challenging, it was achievable, and the point cloud data proved to be accurate and usable. Meanwhile, the 3D model was entirely unusable and had to be recreated from scratch because the adjustment process would have taken more time than starting anew.

The overall cost of this incident not only included financial expenses but also encompassed wasted time and project delays. The challenge of rearranging machinery and finding alternative solutions, along with the need to re-survey the as-built drawings using total stations, adjust the point cloud data, and recreate the 3D model, was significant.

Key Lessons Learned from Implementing Laser Scanning to BIM

The key lessons learned from this case emphasize that both 3D laser scanning and 3D as-built modeling significantly impact the accuracy of the final results. Therefore, the optimal approach is to have both teams operating ideally within the same company, allowing for the sharing of cross-checking information regarding discrepancies and prompt adjustments.

Ultimately, to achieve an accurate as-built drawing, both teams must possess experience and expertise not only within their own domains but also a deep understanding of the requirements of other teams, as their data serves as input for the subsequent stages. (This proposition was previously mentioned in the article “Why 3D Laser Scanning Requires Specialized and Experienced Providers?“)

About the Author:

Nguyen Huynh (Rainer)

As the Co-Founder and Chief Executive Officer of VMT Solutions, SSIFT Vietnam, BlackSwiss Vietnam, and Victoria Measuring Solutions PTY LTD (Australia), I completed my Master’s program in Technical and Vocational Education and Training (TVET) in Germany in 2007.

With over a decade of experience in point cloud processing and BIM services, I am passionate about tackling complex challenges and developing innovative workflows to enhance accuracy and detail in point cloud-to-BIM conversion.

At VMT Solutions, we are committed to delivering high-quality services that provide exceptional value, especially for surveying companies. We focus on building mutually beneficial partnerships, ensuring that our clients receive customized solutions tailored to their specific needs. Every day, I strive to push the boundaries of the industry, continuously improving our methods and exploring new ways to optimize the services we provide.

Recent Posts

Tag Cloud

We are proud to have

satisfied customers.

„Your plans are perfect; I’ve never seen anything like this before. These are drawings of the highest quality, I must say. I want to express my sincere thanks once again for your work.“

VMT modeled a large industrial building in 3D for our research project. We provided DWG plans to VMT, and they delivered a highly detailed model, including the building envelope, interior walls, openings, and stairs. We had previously contracted a German company for the same object, but unfortunately, it didn’t work out. I was relieved and pleased that VMT handled it so reliably. Thank you for the excellent work and the truly fair price!

Very reliable company, courteous staff, and top-quality work. Our plans were created quickly and accurately. Thank you for that. Highly recommended.

Excellent advice and high 3D modeling quality at a great price-performance ratio… What more could you want? I can highly recommend them…